Industrial automation

The industrial environment involves a wide range of situations when automation systems improve labour productivity, ensure enhanced reliability and operational safety. Along the times, we have successfully developed both new projects and improved existing production capacities.

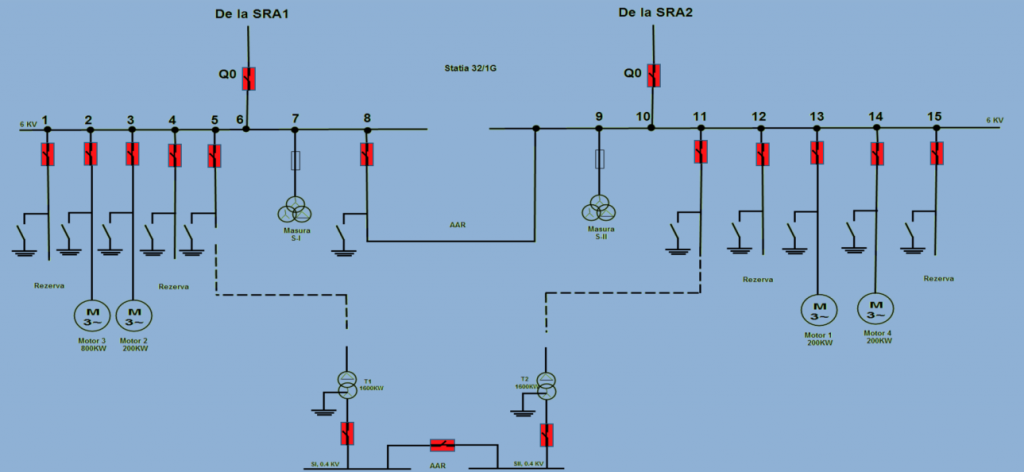

The automation projects we have performed include and develop elements such as PLC programming, AAR automation and electro-generating groups, SCADA and UPS systems, condenser batteries, engine control and adjustment, distribution boards.

Our specialists are experienced in the development and implementation of PLC applications:

- SIEMENS, families S7 and S5, using Step7, WinCC and WinCCflexible as programming environments;

- EATON range XC, XV, using Codesys, Visual Designer and Galileo as programming environments;

- PHOENIX CONTACT, Axioline range, using PCWorx and Visu+ as programming environments.

Experience in the use of smart equipment

Most power equipment, such as energy counters, regulators, etc. have a computer communication interface and may be integrated into a SCADA system along with the PLC, by means of standard or non-standard communication protocols, for which we have developed our own applications.

Reliability. Efficiency. Performance.

Three core values make up the foundation of a dynamic enterprise, geared toward accomplishing the most innovative goals. More than a mission statement, those values materialize into clear objectives, carefully crafted technical solutions from our experienced engineers and, most importantly, successful projects.